Machines

Air knife system

Quickly blow dry surface moisture or grease

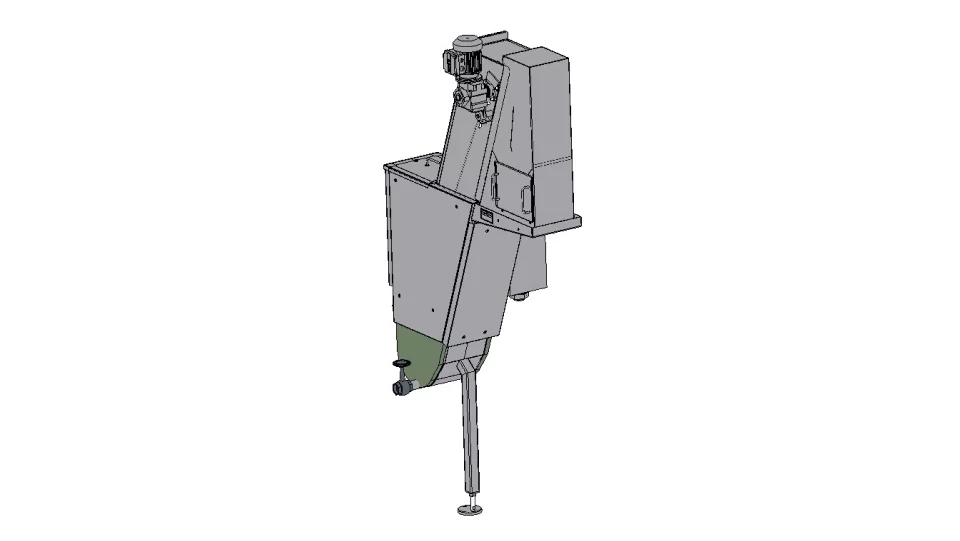

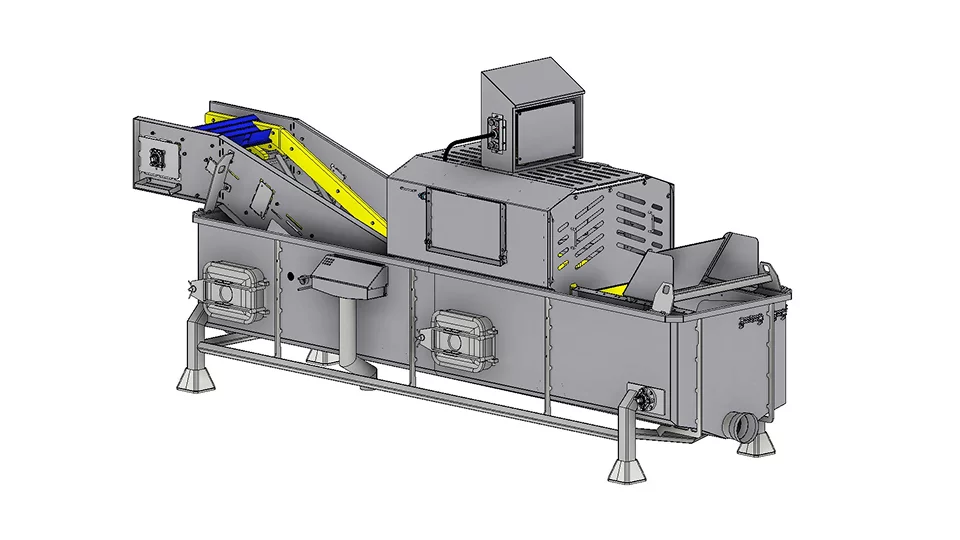

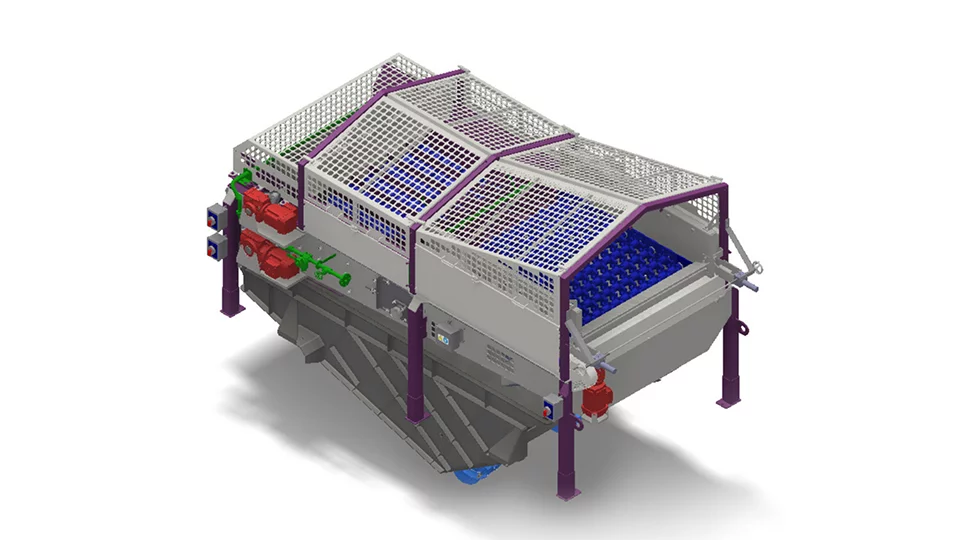

Belt filter

Real-time filtration of frying residues

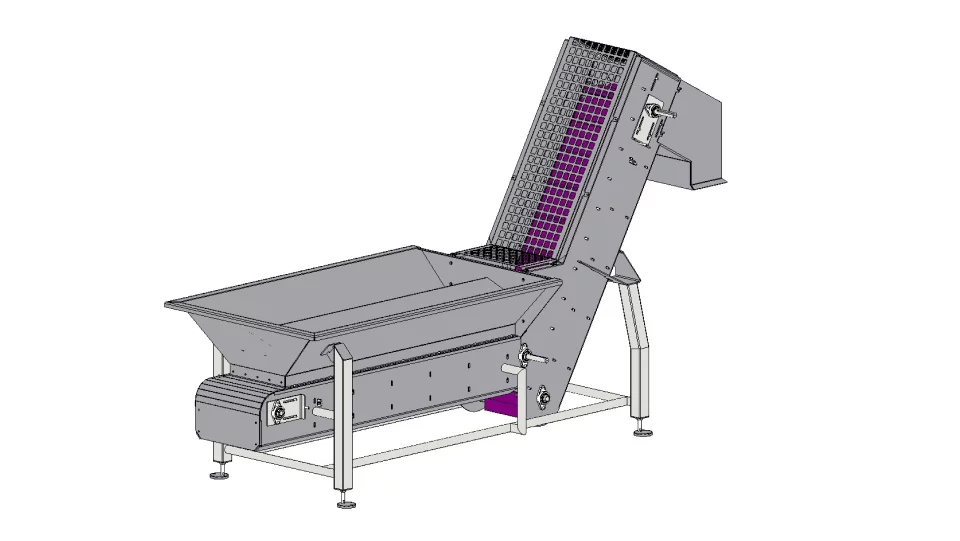

With silo hoist

Precise control of material flow to improve wiring efficiency

With hopper elevator in silo

It integrates conveying and buffering, saving equipment interface

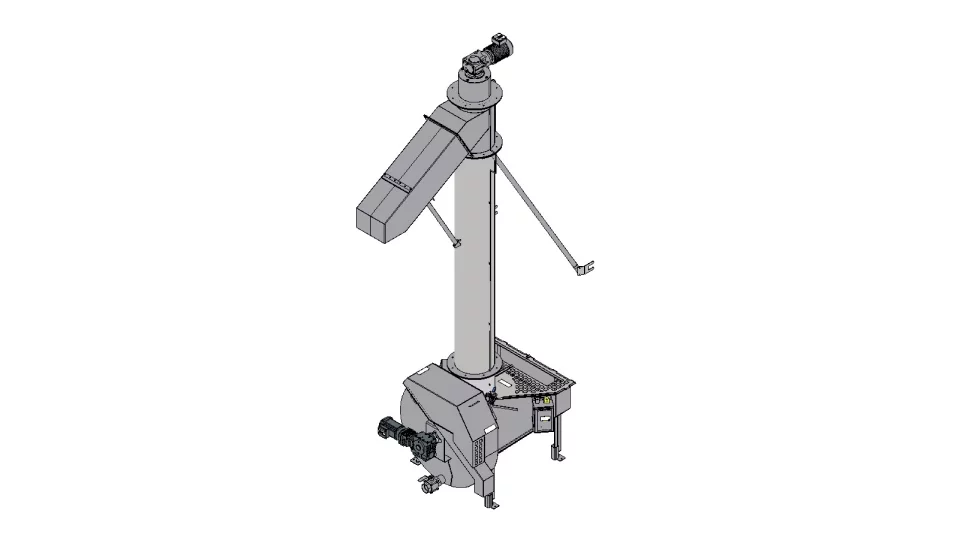

Vertical hoist

Efficient lifting of materials, stable and not scattered

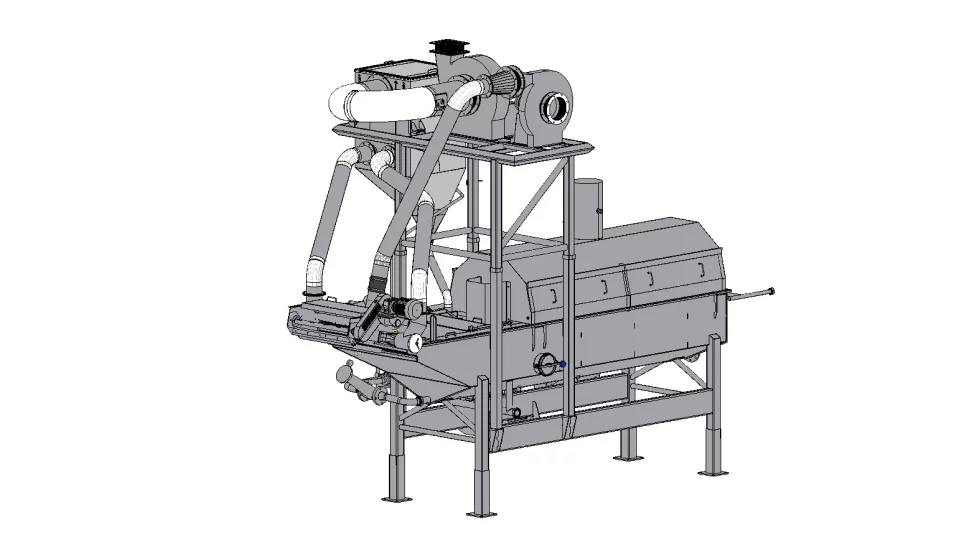

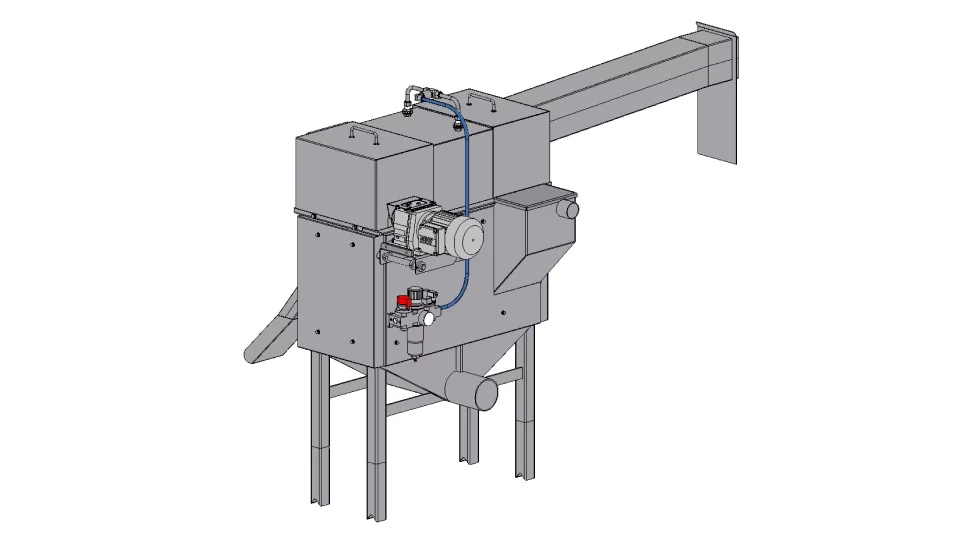

Drum oil purifier

Dynamic circulating filtration system to purify frying oil

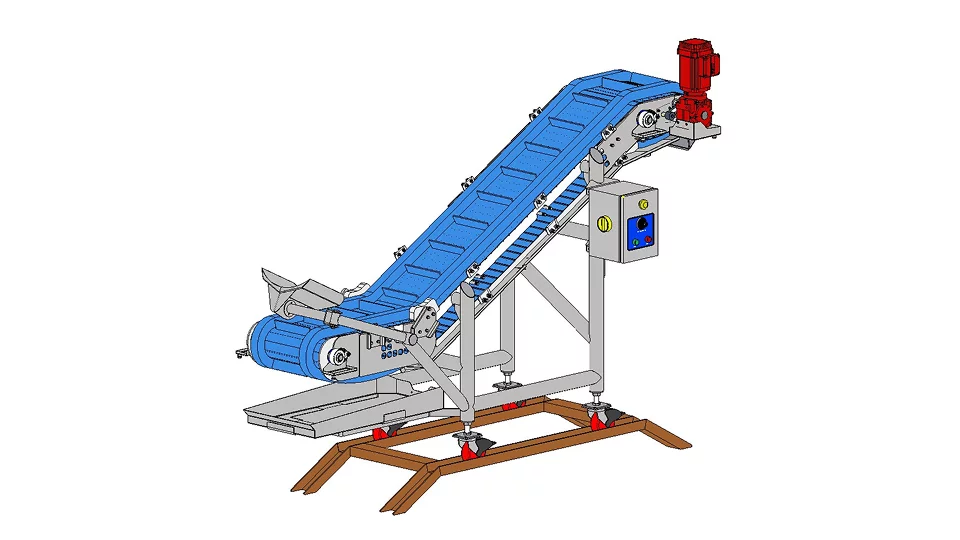

Z-belt conveyor

Integrated solution for vertical and horizontal conveying

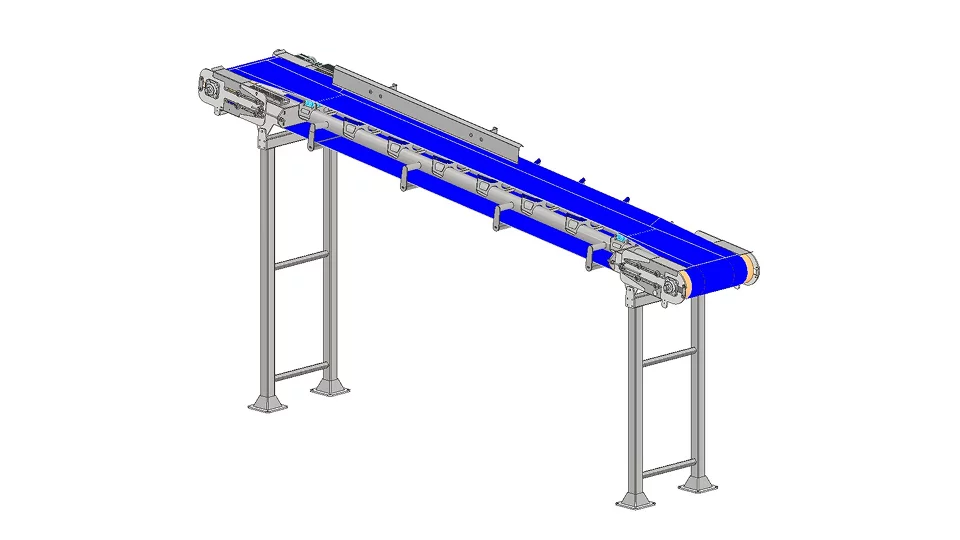

V-belt conveyor

Convey materials evenly to avoid backlog blockage

PEF

Improve cut quality and product consistency

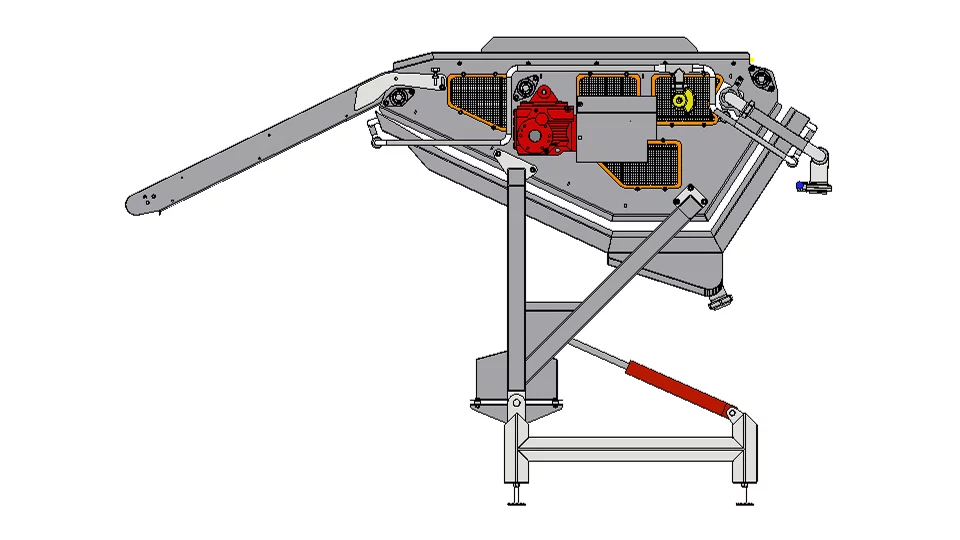

Frying feed conveyor

The equipment is placed at the imported french fryer, which is an indispensable equipment for making french fries, ensuring that the product can slide into the fryer, and the equipment can be rotated to transfer the position to facilitate the switching of coated and non-coated production needs

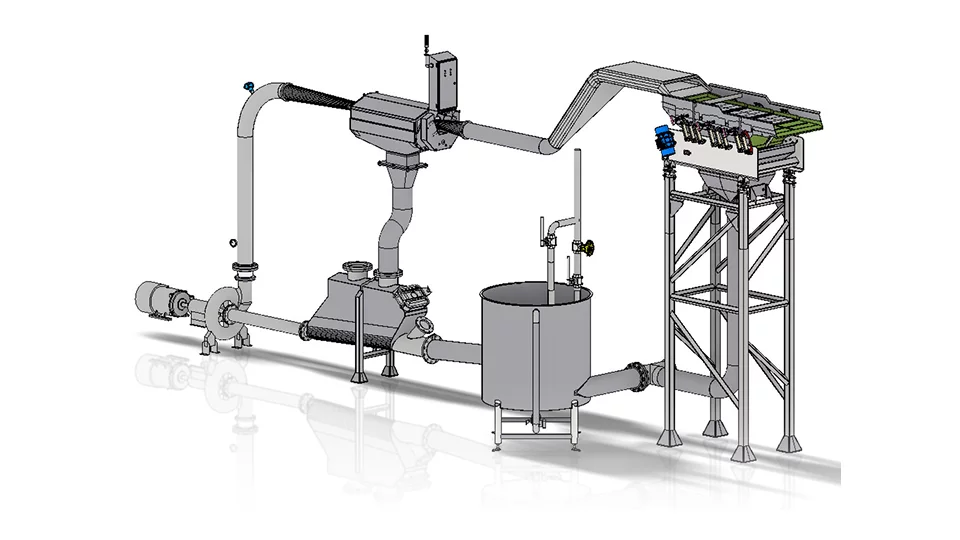

Waterjet system

The waterjet cutting line is composed of a conveying pump, a conveying pipeline and a cutter head, which can cut the material into strips, sheets, wedges or other possible shapes, with fast cutting speed, low material loss, automatic switching of cutter heads, easy operation, flexible assembly line, and a capacity of 3 to 15 tons per hour according to different options

Automatic halving machine

After freely setting the size of raw materials such as potatoes and sweet potatoes, the size is screened first, and then the large ingredients are cut in half to ensure the consistency of the final bagged product