High-grade french fries production line

Performance Advantages:

flow path

High-grade french fries Production line flow diagram

Cleaning section

Receiving device

Caching devices

cleaning equipment

Slag removal equipment

Peeled segments

Lifting equipment

Steam peeling

Conveying equipment

Rub and peel

Preheat the section

Light separation equipment

Weighing equipment

Preheat the pan

Conveying equipment

Cut into segments

Grading equipment

Pumping equipment

Strip cutting equipment

Hydrophobic equipment

Starch collection device

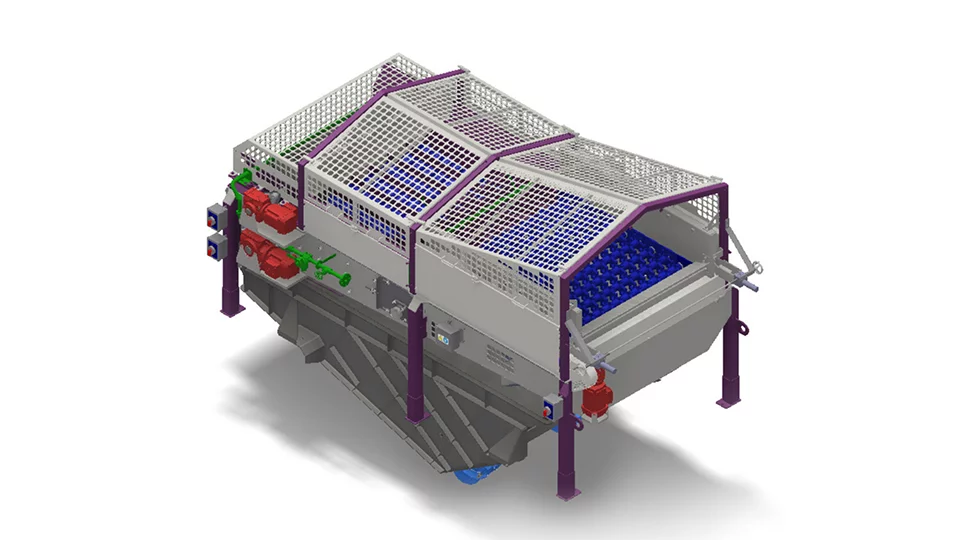

Blanching section

Light separation equipment

Conveying equipment

1# Blanching

2# Blanching

Starch collection device

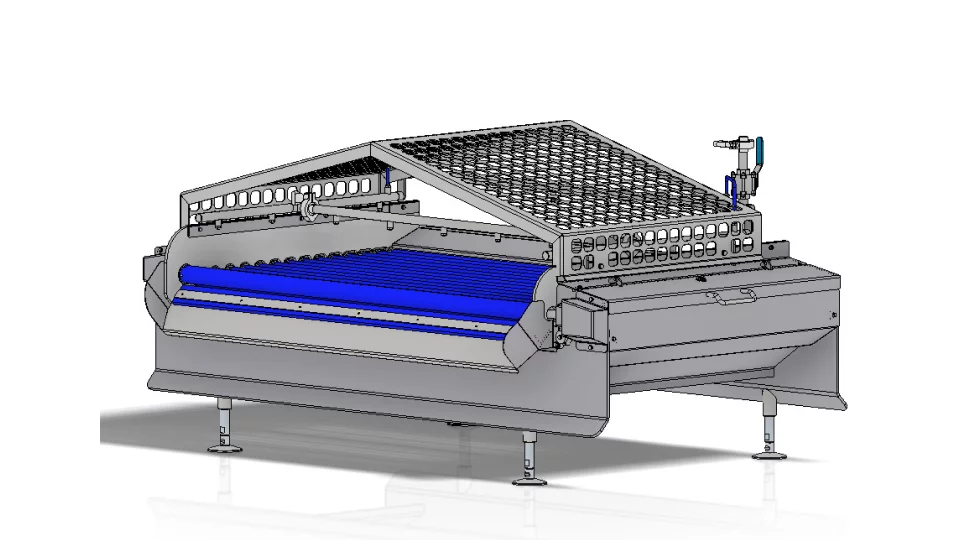

Drying section

Vibrating fabrics

Level 1 drying

Level 2 drying

Coated section

Powder preparation

Powder coating

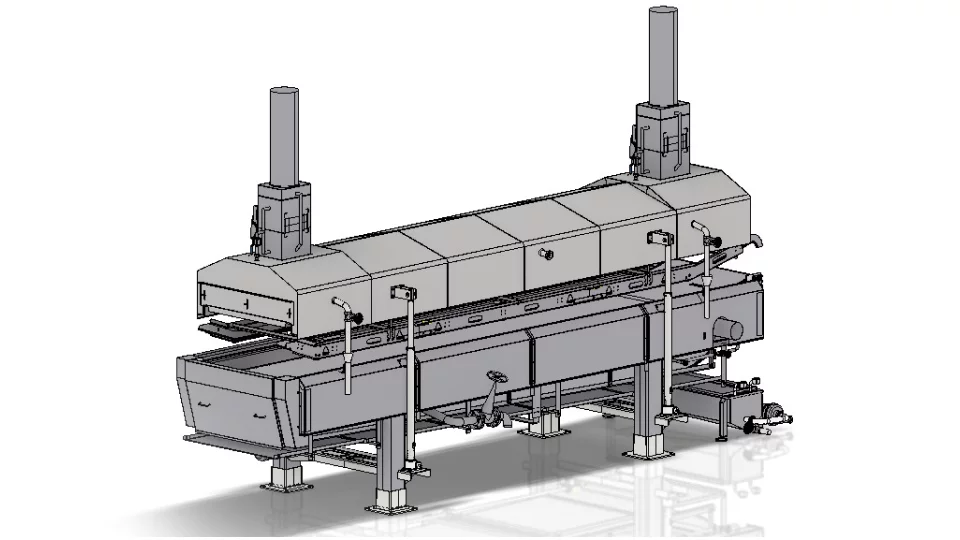

Deep-fried section

Oil storage and supply equipment Class 1 frying

Level 2 frying

Fuel-saving system

Quick-frozen section

Pre-cooling section

Quick-frozen section

Packing segments

Grading equipment

Weigh the packaging

Gold check and re-inspection

Packing and palletizing

Machines on this processing line

Whether you're new to food processing equipment or looking for a more efficient and reliable overall solution, WSBG always puts the customer at the center and listens to every detail. From stand-alone customization to whole line planning, we not only provide equipment, but also provide landing and vision.

Fill in the information below and one of our professional consultants will contact you as soon as possible to turn your ideas into results.

Contact us

Contact Us

Contact us

Telephone: 13752762415, 15689170030

Email: liujun@wsbgcn.com

Nanjing Headquarters

Weisenberg (Nanjing) Technology Co., Ltd

Room 1824-133, D2 North, No. 32 Da Road, Yuhuatai District, Nanjing

Shandong Branch

Weisenberg (Shandong) Food Machinery Co., Ltd

Shunyi Road, Zhucheng City, Weifang City, Shandong Province

Potato deep processing product line

Processing line for potato chips

©2024 Weisenberg (Nanjing) Technology Co., Ltd . Copyright 苏ICP备2024129330号